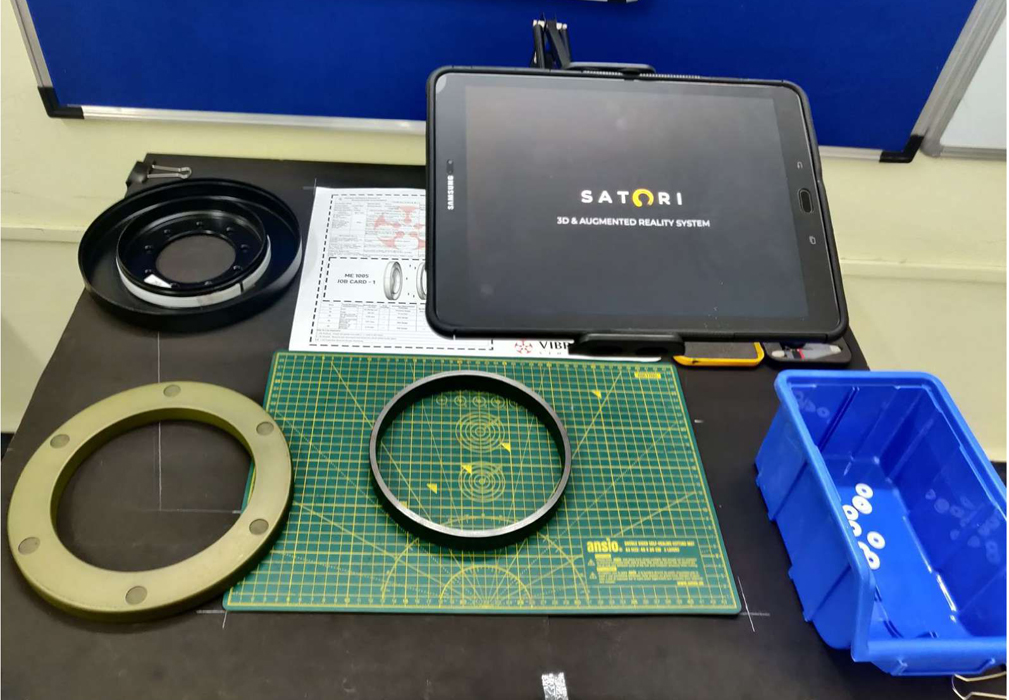

Your Solution for Enhanced Operations

Process Quality & Process Control

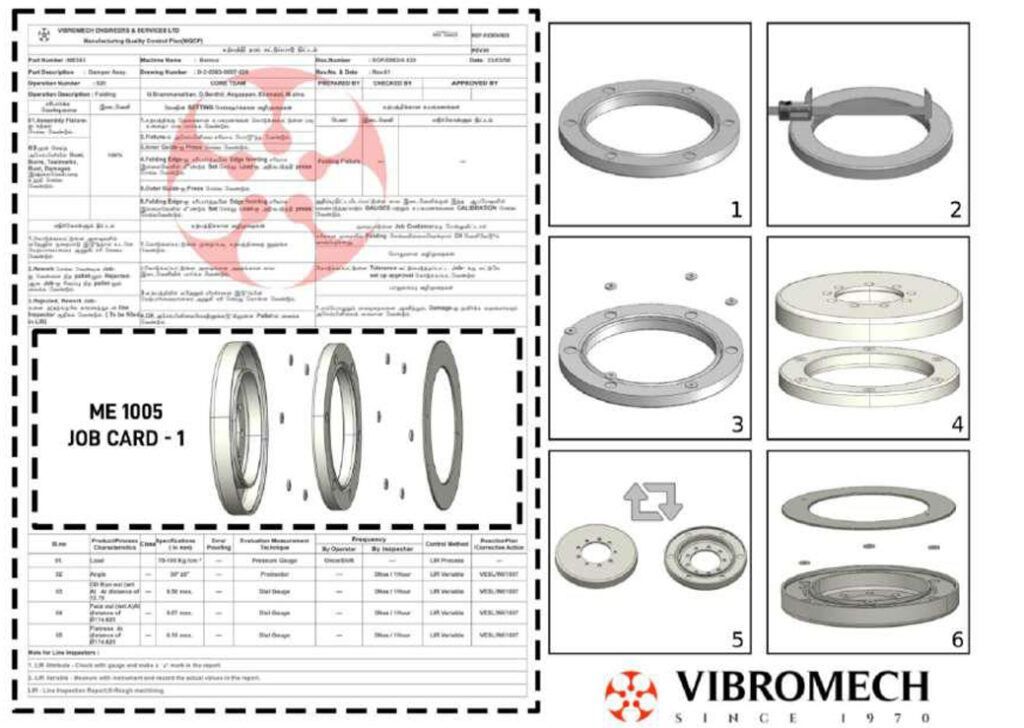

XR SOP

Digital work instructions allow you to Save the environment, improve quality and process control, implement audit, take real-time measurements and more.

XR Service Manual

A Service manual that is purposefully interactive, vastly improves mistake proofing, enables quicker service and updates on the go.

XR Training

TrainingXRtreme transforms corporate training with immersive 3D AR VR XR experiences, eliminating costly travel and disruptions.

Digital Guidance

Key Features of ProductionXRtreme:

- Digital Guidance and Compliance: Ensure adherence to standard operating procedures with real-time guidance and automated compliance checks.

- Advanced Data Collection and Analysis: Collect accurate measurement data and perform in-depth statistical analysis to identify trends and optimize processes.

- Digital Audit and Process Control: Streamline audit processes, eliminate manual data entry, and access SPC charts directly within the software.

- Mistake Proofing: Implement Poka-Yoke mechanisms to prevent errors and ensure product quality.

Key Benefits of ProductionXRtreme:

- Improved Process Quality: Enhance product quality and consistency through real-time monitoring and data analysis.

- Enhanced Process Control: Gain greater visibility and control over your processes with digital oversight and automated compliance.

- Real-Time Measurements: Capture accurate and timely data to optimize performance and identify areas for improvement.

- Efficient Shop Floor Audits: Streamline audit processes with digital evidence and automated reporting.

- Environmental Sustainability: Reduce paper consumption and waste, contributing to a greener future.

- Maintenance of Digital Manuals: Easily create, update, and distribute interactive digital manuals for improved training and compliance.

- Engaging and Interactive Training: Unlike paper-based manuals, XR software provides immersive and interactive training experiences that are more effective and engaging for employees.

- Reduced Environmental Impact: Eliminate the need for paper, reducing costs and environmental impact.

- Streamlined Processes: Automate data collection, analysis, and reporting, saving time and resources.

- Enhanced Understanding: XR visuals provide a clearer and more intuitive understanding of complex processes, reducing errors and improving efficiency.

- Centralized Knowledge Base: Store all process documentation and data in a centralized digital repository for easy access and management.

Challenges

Unavailability Of Talented Personnel

- Only experienced personnel can understand and explain

technical nuances. - Difficulty in visualizing specifics of the process.

Feedback and Audit

- Inability to obtain feedback

- Difficulties in maintaining records

- Difficulty in digitalization of paper records

Measurement, Attribute Data And Mistake Proofing

- Additional efforts to measure and record data

- Detection of error conditions requires external system

- Mistake proofing/Poka-Yoke requires external systems

Digital Audit and Process Control

- Take measurements as directed by the system at the correct location.

- Capture measured data.

- Store evidence of completed process as images for auditPerform a full range of statistical analysis